Modico will showcase its range of high-tech stamp machines and stamp consumables, at the Sign Africa Durban Regional Expo, taking place from 6-7 March at the ICC Durban.

Modico uses a new and revolutionary manufacturing method for stamps: the permanent stamp – also known as Flash Stamp, because it is produced with a flash-unit. Sharp and even imprints of best quality characterise these kinds of stamps.

How the Modico stamp works:

The ink pad is placed behind the printing plate which is made of a microporous special foamed material, that stays ink-permeable only at the unexposed areas. The exposed areas are ink-impermeable. If you press the stamp, the ink will be dispensed through the ink-permeable areas of the text plate onto the paper. This is why there isn’t any loss of quality, which is the result of the uneven transfer of ink from the ink plate onto the text plate, like it is common with conventional wooden – or self inking stamps made of polymer or rubber.

A new modico® is created in three minutes. Its imprint is razor-sharp. Its resolution gains up to 600 dpi. Graphics, grey scales, photos, personal signatures and fonts down to 4,5 points are reproduced precisely. It uses an intelligent technology that makes a profit margin of up to 200 percent possible.

All you need is a laser printer, the modico-exposure-unit and a little bit of creativity.

The modico is based on an the flash process, allowing an emission-free designing of your individual stamp. An energy – and space-saving exposure-unit does the job in just a few minutes, completely without any chemicals. Even when used daily, the modico remains ecologically friendly.

Advantages of the stamps include:

- Fast production in three minutes from the artwork to a completed stamp.

- Easy application.

- All ink colours are the same low price.

- Revolutionary design modico® combines perfect function with aesthetics and ergonomics. Models in different sizes, including the world’s largest self-inking stamp,and up to five different variants of colours are available.

- Award-winning design: the modico golf ball stamp is the winner of the 2012 Red Dot Design award.

- Brilliant imprint quality: the stamp is even able to produce half-tones in several shades.

- In addition to the six different stamp inks, stamps with fast drying inks are also available. With those you can stamp on a variety of materials, e.g. photo paper, metal, synthetics, wood, ceramics, textiles etc.

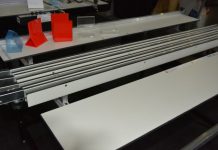

Modico Exposure Unit

The modico exposure unit fits in very small offices and business premises. It is compact, easy and safe to use and has the newest microprocessor-controlled technology. It has a wide range of applications, for microporous text plates and various brands of stamps.

Advantages of the modico Exposure Units:

- Small investment

- No current costs, no service contract needed

- Up to 50000 exposures per lamp (replaced for free by Modico Southern Africa)

- Usable for every flash Stamp

- High quality product made in EU, with 2 yearr guarantee.

Entrance to all the Regional Expo’s is FREE. Pre-register online, attend the Expo, and you could win R1000 in cash: http://www.practicalregistrations.co.za/index.php.