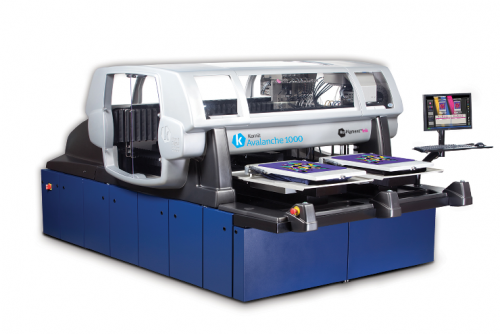

Kornit Digital has brought the highest speeds to the direct-to-garment market with the new Avalanche 1000, which it will launch at FESPA 2013, taking place from 25-29 June.

Designed for 24/7 mass production operation, the Avalanche 1000 is the fastest direct-to-garment printer ever made by the company. Besides its outstanding productivity, it features new piezo-electric print-heads, a back-up battery system and an integrated professional humidity system for greater efficiency.

The Avalanche 1000’s enhanced speed and performance characteristics enable a single operator to produce printed garments and fabric cuts at exceptional speeds, making it the most productive direct-to-garment printer in the market. The Avalanche 1000 uses the company’s NeoPigmentTM process which is more environmentally friendly and efficient than machines that require additional pre-treatment and drying processes before being ready for print.

Designed for the mass production of garments, Kornit’s Avalanche 1000 has dual pallet industrial production capability, and is a very robust platform designed for heavy duty use. The print-head array, equipped with 24 Spectra Polaris heads, generates very high speeds and excellent print quality. An integrated humidifying system makes the machine resistant to the daily variations in room climate, and a back-up battery system allows the main power to be turned off when the machine is not being used. It features a print area of up to 90 x 60cm and 12cm wide pass printing. An automatic height adjustment mechanism allows printing over buttons, zippers and other protruding objects. It prints up to 300 light and 170 dark garments per hour. With all those new features, the Avalanche 1000 is perfectly suited to be used all day, every day and for all volumes.

Another new member of the Avalanche product family will be the Kornit Avalanche Hexa, making its first public appearance at FESPA. The Avalanche Hexa is a six-colour direct-to-garment printer featuring additional red and green channels with an increased gamut for improved colour saturation and spot colour handling, making it the ideal direct-to-garment solution for the fashion, sportswear and promotional materials printing markets.