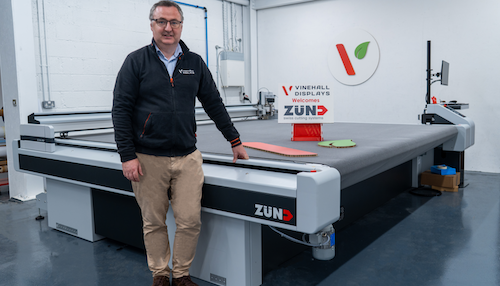

Vinehall is known for its ability to deliver complex projects with consistency, precision and reliability. The business, a second-generation, family-run conference, exhibition and event production company based just outside Dublin has invested in a Zünd G3 3XL-2500.

According to Gerard McElhinney, Managing Director at Vinehall, the company’s aim is clear. ‘We are a true one-stop shop for conferences, exhibitions and events. Everything from concept and design through to print, fabrication and build is handled in-house. That level of control is critical when working with large brands that expect absolute reliability.’

Sustainability is an increasingly important focus for the business, and Vinehall’s investment in Zünd cutting technology has played a key role in supporting this. The Zünd system has helped to significantly reduce waste through precise cutting and efficient nesting, while also enabling greater use of eco-friendly materials such as Re-board® and SWEDBOARD®.

McElhinney said, ‘Reducing waste was a key driver for us and the Zünd has made a real difference to how efficiently we use materials, while maintaining the quality our clients expect.’

Silicone edge graphics are a major component of Vinehall’s exhibition work. Previously, cutting silicone by hand was time-consuming and prone to inconsistency. Since installing the Zünd system, this process has become faster, more accurate and far more reliable, freeing up skilled operators to focus on higher-value tasks and improving overall productivity.

The Zünd has also expanded Vinehall’s production capabilities, enabling roll-to-roll cutting and the processing of a wide range of materials, including Foamex and Dibond. Precision is particularly critical for matrix panels, where even small inaccuracies can cause issues during installation.

McElhinney explained, ‘Our clients trust us to deliver, that means we need machinery we can trust for absolute precision and quality. The accuracy we achieve on the Zünd gives us total confidence on even the most complex projects.’ Looking ahead, the company is also exploring new opportunities in acoustic felt and acoustic panels, an area it plans to develop further in 2026.

|

LOCAL DISTRIBUTOR |