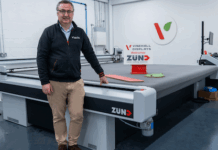

Ilisna O’Reilly, Sales Manager Southern Africa at NUtec Digital Ink, discusses product end of life (EOL), and why this is not an indication that the product has failed.

Have you ever found yourself using a product for years without a single issue, only to be told that it will no longer be available? In the printing industry, this scenario is all too familiar.

Product EOL is often perceived as a failure, but in reality, it is usually a sign that technology, chemistry, and industry expectations are moving forward.

Across the signage and digital printing industry, materials and inks are sourced globally and continuously evolve. In digital inkjet printing specifically, product EOL is rarely just a commercial decision. It is driven by a complex interaction between printhead technology, ink chemistry, regulatory requirements, and changing application demands. Even the most successful ink formulations eventually reach a point where continuing production no longer makes technical or strategic sense.

Several factors can ultimately determine the fate of an ink product line:

Equipment And Printhead Evolution

Inks and hardware are inherently linked. As new printhead generations enter the market, ink formulations often need to be adapted to ensure optimal performance. At the same time, older printers become harder to support as spare parts are discontinued. As customers upgrade their equipment, demand for legacy inks naturally declines, reducing production volumes and making once-top-selling ink sets less viable.

Raw Material Availability

Pigments, resins, dispersions, and additives can be discontinued or reformulated by suppliers. Even minor changes can impact colour consistency, viscosity, drying behaviour, or jetting reliability. In many cases, maintaining identical performance becomes impractical, forcing manufacturers to reformulate or discontinue the product altogether.

Regulatory And Environmental Pressure

Regulation is one of the most significant drivers of ink EOL. Increasing restrictions on VOCs, solvents, and substances of very high concern (SVHCs) across regions mean legacy inks may no longer meet compliance requirements. Frameworks such as REACH, Proposition 65, and RoHS place growing responsibility on manufacturers and end users alike. When compliance requires extensive reformulation, product replacement often becomes the most responsible and sustainable solution.

Application And Substrate Evolution

The rise of low-energy plastics, coated films, and recyclable materials has changed performance expectations. Customers increasingly demand strong adhesion without primers or pre-treatment, along with improved durability, chemical resistance, and outdoor longevity. Faster curing, lower odour, and third-party certifications such as OEKO-TEX or GREENGUARD are more frequently requested by PSPs.

Manufacturing Economics

As customers migrate to newer ink technologies, volumes on older ink lines decrease. Lower production volumes drive up manufacturing costs, making legacy products less competitive and harder to justify from a business perspective.

By consolidating product lines to offer the latest technology, manufacturers can offer faster production lead times to customers with shorter delivery lead times and even produce stock to be available off the shelf, further enhancing the customer experience.

EOL, therefore, is not an indication that a product has failed. It reflects an industry that is advancing; technically, environmentally, and commercially. For print service providers, embracing future-ready ink technologies as they become available is not just a necessity, but often an opportunity to stay competitive in a rapidly evolving market.

Disclaimer: Any technical advice or opinions shared are my own and are not to be considered as official guidance from NUtec Digital Ink.

C1W Initiative

Change 1 Woman (C1W) aims to empower women in the branding, print and signage industries. As part of this initiative, Sign Africa would like to spotlight women-focused content like this piece. If you have any trend/business articles related to the signage, branding and printing industries, please email content to: meggan@practicalmedia.co.za. Follow C1W on Facebook and LinkedIn for more updates.

| MANUFACTURER NUTEC DIGITAL INK Tel: +27 21 763 6990 Email: info@nutecdigital.com Website: http://www.nutecdigital.com  |