The new Roland TY-300 direct-to-film (DTF) printer delivers stunning graphics and bold designs for heat transfer onto a wide range of materials, including cotton, polyester, denim, nylon, rayon, and more. Users can transform custom apparel and textiles with technology that enables them to produce vibrant colours, razor-sharp text, and fine details with unprecedented cost effectiveness, speed, and efficiency.

The TY-300 offers high print quality and reproduces colours, detailed images, and even smaller text with amazing accuracy. It prints at speeds up to four times faster than competitive models, allowing for optimum productivity.

Low running costs and reduced ink consumption during printing/cleaning make the TY-300 very cost-efficient. It creates durable apparel and textiles with a ‘soft hand’ feel, natural finish, and outstanding washability.

Benefits:

– Vibrant colours: create bold, vivid prints for any type of fabric with Roland’s exclusive DTF inks.

– Ultra-fine detail: print small letters, intricate designs, and photographs with precision.

– Maximum productivity: stable, high-quality printing with fast performance and minimal downtime.

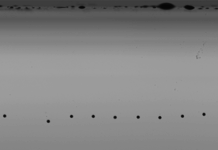

– Perforated sheet cut: save time by integrating perforations directly into prints.

– Lower operating costs: produce more with less thanks to ultra-efficient operations and automatic maintenance.

– Intuitive design: equipped with user-friendly RIP software, a colour LCD touch panel, and convenient features.

The TY-300 is part of Roland DG’s full DTF solution, with RIP software, DTF film and powder, and an optional shaker/heater unit for automated DTF transfer production. Reduced ink waste and improved efficiency equates to noticeably lower running costs.

|

LOCAL DISTRIBUTOR

|