The recent adoption of a Mimaki JFX600-2513 industrial UV LED flatbed printer has marked a turning point for CEMAB, enabling the company to achieve unprecedented levels of speed, quality, and sustainability, particularly in the pioneering field of direct-to-wood printing.

Based in Italy, CEMAB has consistently combined artisanal heritage with cutting-edge innovation to deliver displays that are both functional and highly customised. For over 40 years, the company has been redefining wooden display manufacturing, establishing itself as one of the largest producers in Europe.

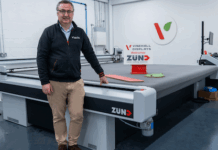

‘The quality of our work is built on innovation and precision. The Mimaki JFX600-2513 printer has allowed us to guarantee both exceptional speed and a level of print quality on wood that was previously unimaginable,’ said Alessandro Leccese, Managing Director at CEMAB.

Traditionally, wooden displays required laminates, vinyls or adhesives to achieve decorative finishes, often adding cost, complexity, and production time. With the Mimaki JFX600-2513, CEMAB can now print vivid, high-definition graphics directly onto wooden substrates, whether smooth or irregular, eliminating unnecessary steps in the process.

The result is a faster, more efficient workflow. With a print width of 8cm per pass and speeds of up to 200sqm/hour, CEMAB has scaled its production to more than 500 displays per day, meeting even the tightest delivery schedules while maintaining flawless detail and colour reproduction. ‘Speed has become one of our key competitive advantages. With the JFX600-2513, we can produce far more in less time without compromising quality. We are faster, more efficient, and still delivering the quality and precision our customers expect,’ explained Leccese.

The integration of the JFX600-2513 was made possible through CEMAB’s long-standing collaboration with Mimaki’s exclusive Italian distributor, Bompan. From installation and training to continuous after-sales support, Bompan ensured that CEMAB’s transition to this new technology was smooth and reliable.

CEMAB’s innovation strategy is closely tied to its environmental responsibility. By eliminating the use of adhesives, the JFX600-2513 reduces material waste and lowers environmental impact. Mimaki’s eco-friendly UV inks further enhance sustainability, while an on-demand production model minimises stockholding and optimises resources. ‘We have always aimed to do our part for the environment. With the JFX600, we reduce waste while delivering a superior product,’ added Leccese.

By merging craftsmanship with cutting-edge printing technology, CEMAB has not only enhanced its operational capabilities but also unlocked new creative opportunities in wooden display design. ‘This integration of craftsmanship and technology is setting a new benchmark in the sector, proving that even in traditional industries, innovation is the key to staying ahead in a competitive global market,’ concluded Leccese.

|

LOCAL DISTRIBUTOR |