Midcomp has become a Gauteng reseller for Clear Solutions, a HandTop distributor based in the Western Cape. Building on this partnership, Midcomp has installed a HandTop HT2512 FR5 UV flatbed printer at Fineline Design.

‘We are proud to announce a new strategic partnership with Clear Solutions, reinforcing our ongoing commitment to providing the most reliable and effective technology offerings in the entry-level and traditional flatbed printing market,’ said Rob Makinson, Midcomp Group CEO.

‘This partnership, already in effect, aligns with our mission to offer a non-conflicting, best-in-class portfolio of products that meet the evolving needs of our customers. By joining forces with Clear Solutions, we now bring on board a trusted name with the largest install base in South Africa for a product that has truly proven itself in the local market. Their solutions have been tried, tested, and trusted throughout South Africa, and we are excited to work alongside Gavin Petersen (from Clear Solutions) and the team to bring these products to our customer sites. With this collaboration, we continue to expand our reach while delivering unparalleled value and performance in the wide format print and flatbed space.’

With Ricoh Gen6 printheads, HandTop flatbed digital printers can print in high speed as well as high precision in six colours at 1200 x 1200dpi. The optional white ink mode and varnish mode adds multifunction usage for UV printing. HandTop’s UV flatbed printers also deliver photo quality prints.

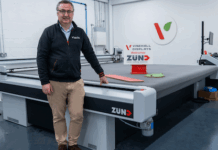

According to Midcomp sales agent, Gavin Lee, who oversaw the installation at Fineline Design, the HandTop HT2512 FR5 allows Fineline Design to take their business to the next level: ‘The machine allows for printing onto a wide range of rigid substrates, which was previously not possible, and allows for multilayered printing, vibrant colours, and exceptional precision.’

Printing is possible on rigid and flat flexible materials. The HandTop HT2512 FR5 was purchased with white printheads, which allow for spot white, white underflood and white overflood applications. The flatbed printer is upgradable in the field by allowing for extra printheads to be fitted for additional speeds of up to 75 square metres (sqm) per hour. Printing is possible on substrates up to 100mm thick with automatic hight adjustment.

Lee added that the printer can easily be operated by one person, and includes a powerful vacuum mechanism with four vacuum zones, which can be activated independently, with no need for masking.

Fineline Design’s Managing Director, Manny De Souza, commented on the benefits of the machine: ‘The HandTop is a true flatbed, with a really great vacuum, so it gives us great stability when printing on different substrates, even ones that don’t lie 100% flat.’

‘In terms of production speed, we can set up the machine how we want to with the configuration of the printheads. We decided to do a double row of CMYK, and one row of white that currently gives us – at good print quality – about 45sqm per hour. If we print at production mode, we can produce at almost 58sqm, which is great.’

De Souza added that as the business grows, the company can increase that production by adding another row of CMYK, and adding more white printheads etc. This would increase the speed to over 75sqm an hour.

De Souza said that they can also produce high volumes at lower rates because the running cost of the printer is so efficient.

He added that the business can now create new products, such as packaging and display boxes. Additionally, they have started to explore the art space, as the printer can do layer printing, and print on all substrates directly, saving time by cutting out the process of vinyl application, for example.

‘Creating art is something that I’m passionate about, because it’s about high quality, niche production. It is something unique compared to just flat print vinyl with a different laminate, which is what everybody else does. We want to differentiate ourselves with the HandTop printer by creating bespoke products. It even allows us to do ‘one-off’ products. Our customers will pay us for our time and uniqueness,’ he added.

‘The HandTop printer takes us into a different business-to-business market where we can service the signage market instead of only business-to-consumer. There’s many businesses out there that can only print roll-to-roll and that don’t have the capital to go into the flatbed space. Now they can use us as their print factory and they essentially become a reseller. I can provide services directly to the industry, such as printing directly onto ABS, Chromadek, ACM, PLEXIGLAS® etc. I can even print on ceramics like tiles, where a regular print shop maybe can’t do that because they have the normal roll-to-roll technology.’

‘The service from Midcomp is absolutely exceptional. I bought my first machine from them in 2005, so there’s a lot of history, a lot of trust, and a lot of synergy. We strive for the same thing: good service, good equipment, and being there for the people that support you,’ said De Souza.

‘Fineline Design has been a loyal Midcomp client for many years. We’ve had the privilege of watching their remarkable growth into one of the leading players in their market segment. As early adopters of HP Latex technology, they continue to set the pace by investing in cutting-edge solutions,’ said Lee.

|

LOCAL DISTRIBUTOR |

FINELINE DESIGN

+27 11 794 4929

info@finelinedesign.co.za

www.finelinedesign.co.za