For more than 30 years, Flying Colours, a specialist in artwork and colour separation services for printers worldwide, has been at the forefront of this evolution. Now, partnering with Kornit Digital, the company is demonstrating how decades of screen-printing expertise can unlock the full potential of mass digital production.

‘Digital printing is no longer just an alternative, it’s a new standard for quality, speed, and creativity,’ said Engin Ibrahim, Flying Colours founder.

The apparel production market is shifting rapidly under the influence of consumer demand for personalisation, sustainability, and fast fulfilment. Shorter runs, complex designs, reduced waste, and premium quality are no longer optional, they are expected.

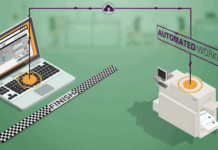

Kornit’s Mass Digital Production technology meets these challenges, enabling printers to respond to brand and consumer needs with on-demand, cost-effective, sustainable solutions. Rather than competing with screen printing, Kornit Digital’s systems complement and expand capabilities, opening the door to designs and effects that traditional methods cannot achieve.

Artwork and file preparation are at the heart of Flying Colours’ expertise. The company has supported silk-screen printers and merchandising firms in more than 15 countries, specialising in complex colour separations and digital print files.

Now, as Kornit pushes mass digital production technology forward, Flying Colours applies its expertise to maximise efficiency, reduce setup time, and emulate the look of screen printing at digital speed. This includes tasks such as intelligently removing backgrounds to use garment colours, enhancing tonal detail, and preserving subtle gradients.

Flying Colours recently visited Kornit’s Düsseldorf facility in Germany to create print files demonstrating how closely DTG could emulate screen print quality. The challenge was to produce files that preserved the craft of screen printing while optimising ink usage through Under Colour Removal (UCR) using the garment’s black to replace black ink wherever possible without losing detail.

Jason Beevor, Studio Manager, spent weeks preparing multiple workflows and artwork files before arriving on-site. Over two intensive days he collaborated with Marie Kuehl, Pre-Sales Application Engineer at Kornit Digital, testing different versions of a complex, detail-heavy image.

Day one was dedicated to experimentation and pushing boundaries, perfecting workflows and testing initial approaches. Day Two built on this foundation, focusing on applying all the insights, data and custom Photoshop actions developed the previous day.

It was a full day of printing multiple shirts and designs, observing, adjusting, and evaluating outcomes. The goal was clear: to produce DTG prints that matched the original artwork, retained fine detail and captured the look and feel of traditional screen printing. Through rigorous testing and refinement, Flying Colours developed a formula that successfully worked on an overwhelming majority of designs for Kornit.

After the planning phase of the first day, Beevor was satisfied with the formula that Flying Colours had successfully produced and the eventual end-product stated, ‘By focusing on one complex image first, we could perfect the workflow then expand it across multiple designs. The prints speak for themselves.’

At Kornit’s Düsseldorf facility, Flying Colours tested complex, detail-heavy artworks to prove how closely Kornit’s digital technology could replicate the craft of screen printing, while maximising efficiency.

Through advanced workflows and intelligent under-colour removal, Flying Colours achieved a 50% reduction in ink usage on photographic designs. This breakthrough not only cuts costs but also supports Kornit’s commitment to sustainability: less ink, less waste, lower environmental impact.

‘The real game-changer was the reduction in ink usage,’ said Ibrahim. ‘We sacrificed nothing in order to achieve a more sustainable product. This could change the entire industry.’

|

LOCAL DISTRIBUTOR |