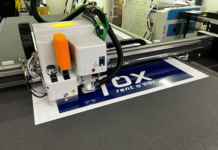

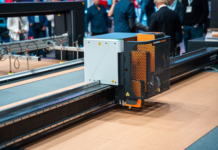

The company has unveiled the new XLF 200 – X/Y Automatic Board Cutter, designed for cutting light rigid materials. Made in Italy, the technology is designed to work in continuous production, supporting up to a width of 200cm (80”). The XLF 200 – X/Y is the high tech solution to perform high-speed linear cuts along the X and Y axes. This ensures high productivity and maximum production in the finishing of digitally printed light rigid panels.

The XLF 200 is capable of handling up to four vertical cuts simultaneously using Fotoba’s cut mark recognition system. Fotoba cut marks, supported by most RIP’s, are printed on the panel enabling the XLF to automatically alignment the cutters on both the X and Y axes. The high accuracy stepper motors guarantee the XLF 200 – X/Y Automatic Board Cutter produces the perfect cut every time.

The new XLF 200 is the ideal finishing technology to support all the latest flatbed inkjet printing presses. The 200cm operational width of the cutter finishes boards perfectly square, even if the boards are not fed into the cutter correctly. XLF 200 technology is designed to align the cut side of the board automatically using FOTOBA‘s Internationally patented sensor technology.

The product is equipped with an easy access display, to enable the operator precise control at any time. A strong and robust structure allows this technology to handle high volumes of work and maintain high the productivity of your printing presses, keeping the workflow flowing.