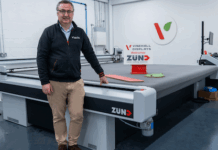

The NSI-4-Africa management team has a collective experience of over 40 years in importing and supplying the South African market with specialised manufacturing equipment. The company’s founder, Ken Bezuidenhout, pioneered CAD software, dye-sublimation, solvent printing, textile printing and channel letter bending in South Africa. He shares his career highlights and the key to business success.

Early Life

Bezuidenhout grew up in Livingstone, Zambia. He left school in grade 10, after his father passed away, and his mother couldn’t afford to keep him in school. He then started an apprenticeship in South Africa at ISCOR in Pretoria in 1966, after not being able to find a job in Zimbabwe.

While doing an apprenticeship, he attended night school to fill in the gaps of the education he’d missed out on, and passed matric (NTC V). Soon after completing his apprenticeship, he started as a mechanical draftsman in a drawing office, and later did various jobs that specialised in mechanical engineering and plant design. By 1977, he became involved with computers, namely programming – being the engineering part of the team bringing out the first desktop computer aided drafting system in the world. He credited the ‘brilliant programmers’ at SKOK Systems for this milestone. At one point, they were the biggest reseller of HP plotters in the world.

Career Milestones

In 1993, Bezuidenhout joined Protea Graphics and reached the level of national sales manager. In 1998, he then decided to start his own business. ‘My wife and I jumped on a plane to China to find a vinyl cutter supplier. In those days, just Roland DG, Summagraphics and Graphtec had them. I brought them back to South Africa, and did very well.’

When the first textile printing technology was introduced in 1997 at DPI conference in USA, Bezuidenhout brought back the first printer that printed directly onto cotton. However, it was a rather complicated technology for its time, considering the steaming, and complexity of getting the colours just right. Although he sold one printer, it was returned soon after by the customer for the aforementioned reasons, but he managed to then sell it to a happy customer in Cape Town. ‘That was my first introduction to textile printing,’ he said.

The next milestone in his career entailed travelling to South Korea in 2002 and securing an agency for roll-to-roll, wide format heat presses, some of which are still in operation and supported today. He returned to South Africa and converted a Mutoh printer to a bulk ink system with dye-sublimation ink, and began to specialise in selling dye-sublimation printing systems.

‘It took a lot of experimentation. There were many sleepless nights to try and get the colours right and keep the ink flowing. I found people internationally that could supply me with the bits and pieces that I needed.’

‘I’m always guilty of finding something new, and ending up being the only one excited about it. Everybody else had a lukewarm reaction to digital dye-sublimation technology, complaining that there were limited applications that their customers were not asking for it, and asking why I wanted to do dye-sublimation when screen printing was much cheaper.’

Bezuidenhout however insisted on thinking laterally, given the opportunities to print on flags, linen, and sports outfits, to name a few. He also learnt from experts and specialists in Germany, who had an advanced dye-sublimation skillset.

His business in the marketing of dye-sublimation systems, solvent printers as well as as vinyl cutters, helped him advance on his own, until dye-sublimation equipment started to become freely available in South Africa, causing profits to decrease.

The Next Step

Bezuidenhout moved on to the next thing. ‘We imported the first low cost solvent printers to South Africa. That was around 2002, when my son Shawn and I went over to Asia and found quality solvent printers at a reasonable price. At that time, we were among the first very few South Africans on the plane. We found that when we were on a plane in 2006 to China to attend an expo, half the passengers on the plane were our customers and opposition.’

However, the father and son team were not discouraged, and continued in the solvent space, getting repeat business from customers who wanted to buy specifically from them for the service and back-up support.

Channel Letter Bending

After testing different versions of solvent printing technology, and adding a few modifications, they decided to once again try something different, and entered the channel letter bending space. Once again, people challenged the idea, saying they preferred neon signage, and fabrication of signs by hand.

It would take three years for Bezuidenhout to sell the first channel letter bender, but today the business sells multiple machines a month. Bezuidenhout’s engineering background also helped him locate a factory in Asia that knew what they were doing and could implement the design changes required for the African market. He continued to source technology that may not have been the cheapest, but it was something he and his son were prepared to put their names behind.

Soon after, the letter bending business expanded with media and consumables, such as aluminium coils, profiles, and adhesives. Machines were modified to accept all such consumables: ‘Even if somebody buys a cheap machine on Alibaba, they can’t use all the materials, because it has not been customised. Our equipment is customised for our customers’ needs.’

Soon after, Shawn became involved in the digital labelling and packaging side of the business, bringing the father-son team to where they are today.

Looking ahead, Bezuidenhout said that they will continue to bring in newer technology, which he expects will revolutionise how things are done: creating prints superior to UV printing durability, with new ink, and a new technique on certain substrates. The end products will be used for architectural and factory applications, and for signage that will be graffiti proof, with the ability to wash the graffiti off with solvent and soap without damaging the print. With hopes to launch the technology before the end of this year, they are also planning on opening a business in Cape Town to demonstrate this new technology.

Industry Changes

‘In 2003, you could sell a solvent ink printed PVC banner for R650 per sqm, now you are lucky if you can sell a PVC banner for R100 per sqm. One mistake and your profit is gone. New technologies are about to be introduced in the digital printing industry that will open new opportunities.

Once again, you will hear the same questions, ‘But why this technology? We have not had customer enquiries for this.’ This is the same as before with wide format solvent and dye-sublimation printing. Maybe it’s not apparent now, but in two years, people will be phoning me to say, ‘Hey Ken, have you heard about this new type of technology?”

Business Philosophy

Bezuidenhout’s business philosophy is to rather try something new when the going gets tough, adding that channel letter bending today is as significant as solvent printing was some 20 years ago: ‘With 3D LED signs, you can still make a sign for R1000 and sell it for R3000,’ he said.

He has also observed that at local trade events, companies focus on the same technology, for example, direct-to-film (DTF). ‘It’s all just DTF. Why would you want to sell that when there’s 10 other vendors at an event punting the same thing? The only way to compete is to sell on price. Customers want the cheapest price, but the best service. If you drop your price, you cannot afford good service. Pre-sale, the promise of service is always immaculate. After delivery, customers who make their decision mainly on price soon learn that getting your lower cost supplier to deliver on their after-sales service promises often leaves you frustrated and on your own. But it will be too late as money has already changed hands.’

‘Don’t stick to the same thing forever; when things start getting tough, have something else that can take you to the next level. Try to be there first. If you focus on a specific technology or business area too long, you drain your resources and you won’t have funds to invest in something new. The best time to look for something new is when you’re doing well, and develop that on the side so that when the time is right, you’ve got something else to keep you going. Entrepreneurs are not usually procrastinators. So get out there and identify the next trend.’

Looking Ahead

‘Much of the success of NSI-4-Africa can be attributed to my late daughter, Michelle, who did a fantastic job with media exposure. I miss her dearly,’ said Bezuidenhout.

He added that his son Shawn is also his best friend. ‘We get along great and I’m trying to take a back seat. Although I’m currently running the signage side of the business, while Shawn runs the label and packaging side, I’m trying to pull out. It’s time for me to sit on the stoep with my lovely wife Ena, who has been by my side and supported me for 56 years.’

Hobbies

When he is not working, Bezuidenhout enjoys tiger fishing on the Zambezi river, and loves to be out in nature observing animals and bird-watching.

NSI-4-AFRICA (PTY) LTD

+27 83 774 5292

kenbez@nashakele.co.za

https://www.nsi4africa.com