According to Liezle Barrie, National Sales Manager Consumables, Intamarket Graphics, vehicle wrapping is one of the most demanding applications in wide format printing. It’s where chemistry, material science, and craftsmanship meet. Between stretching, heating, laminating, and outdoor exposure, every component, from ink to adhesive, must perform flawlessly.

In the printing world, eco-solvent and UV printing are often compared. Both technologies have evolved rapidly, yet when it comes to high-conformability wraps with deep curves and post-heating, the choice of ink can make or break the result.

Understanding The Job

A vehicle wrap must:

– Conform over complex curves and channels without cracking.

– Tolerate heat during post-heating and daily expansion/contraction.

– Laminate cleanly and maintain gloss consistency.

– Last outdoors under harsh conditions.

That means ink flexibility, adhesion performance, and durability all matter as much as colour quality.

Ink Chemistry At A Glance

Eco-solvent inks diffuse into the vinyl’s receptive layer, creating a thin, flexible ink film that stretches naturally with the media (Source: Signmaster).

UV-curable inks, by contrast, cure into a cross-linked surface film using ultraviolet light. This creates strong surface durability and instant dry times, but the cured layer is thicker and less elastic, which can be problematic when stretching vinyl around complex shapes (Source: Graphics Pro).

Industry Findings On UV For Wraps

Multiple manufacturers note that UV inks can crack under stress if used on high-conformability wraps.

– Avery Dennison Instructional Bulletin 1.17: ‘Vehicle wrap films must be printed with conventional solvent inks, not UV curable… UV inks cannot be stretched without cracking.’

– 3M Vehicle Application Guide: UV-cured inks ‘may crack if too much heat is used’ during install on rivets or deep contours.

– Graphics Pro: UV-cured films ‘tend to be too brittle’ for full wraps; best suited to flat or lightly curved panels.

Recent advances have brought more flexible UV ink sets (notably LED-UV systems), but even OEMs caution that performance depends on ink, vinyl, curing energy, and stretch control. Unless explicitly approved, UV remains a higher-risk option for complex wraps.

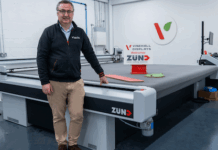

Intamarket’s Real-World Test

We put both technologies to the test using identical vinyl films printed on:

– The bonnet: UV printer (flexible UV ink set).

– The body: Eco-solvent printer.

Results

The UV print (bonnet) looked sharp and vibrant on flat areas. However, the UV print (mirror): cracked and discoloured under heat and stretch, even with flexible UV ink. In contrast, the eco-solvent print: conformed smoothly over curves and channels, maintaining colour and finish.

Adhesive Behaviour: The Hidden Difference

During testing, we noticed another critical distinction: UV prints did not affect the vinyl’s adhesive at all, tack levels and handling matched manufacturer expectations. The eco-solvent prints, however, slightly increased the vinyl’s tackiness due to solvent interaction with the adhesive layer. This made repositioning trickier and required installers to adjust their handling technique.

That difference highlights a key lesson: the ‘best’ ink system isn’t just about print quality, it’s about how ink chemistry interacts with both film and adhesive during real installation conditions.

Choosing The Right Tool For The Job

Use eco-solvent (or latex/resin) when:

– Wrapping full vehicles or complex shapes.

– You need proven conformability and consistent adhesive behaviour.

Use UV (Flexible/LED) when:

– Working on flat or lightly curved panels.

– You need immediate turnaround and rigid-media capability.

Always confirm with your film supplier’s approved ink list and run your own stretch and adhesion tests. Even small variables like curing energy or ink coverage can influence results.

The Takeaway

Our industry research and hands-on testing lead to a simple truth: eco-solvent inks remain the most reliable, flexible, and installer-friendly choice for full-coverage wraps.

UV printing has its place — and with the right combination of film, ink, and process control, it can deliver excellent results on partial wraps or flat surfaces. But for deep curves, complex shapes, and long-term confidence, eco-solvent still leads the way.

C1W Initiative

Change 1 Woman (C1W) aims to empower women in the branding, print and signage industries. As part of this initiative, Sign Africa would like to spotlight women-focused content like this piece. If you have any trend/business articles related to the signage, branding and printing industries, please email content to: meggan@practicalmedia.co.za. Follow C1W on Facebook and LinkedIn for more updates.

|

LOCAL DISTRIBUTOR |