Graphtec’s FC8000 Cutting Plotter has enabled a business to expands it service in wrapping bicycles.

Shack Wrap is owned by avid mountain biker and ex-cycle sales person Nick Shackleton who has built a successful business around the demand for wrapping all kinds of bicycles in a protective film to keep the bike protected from the elements at all times and featured on the ITV TV Show Give It A Year with former Apprenctice host Baroness Karren Brady.

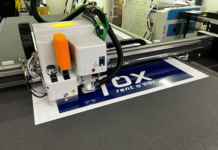

Shackleton uses a Graphtec FC8000 Cutting Plotter to cut templates out of Xpel Paint Protection Film (also knows as PPF) that he then applies to the frame, forks or cranks. This process works to protect the paintwork which keeps the bike looking newer for longer, reduces paint fade and fatigue and can aid in the bike holding a better value when the time comes to sell it on.

Paint Protection Film is widely used in the automotive sector to protect the bodywork of vehicles from stone chips, dirt ingress and to protect against scratches. With high-end bicycles now widely costing upwards of R87,000 (£5000) Shackleton saw a gap in the market to bring this service into the cycle market and so Shack Wrap was born.

Shackleton originally called Graphtec as he was experiencing some problems with the cut performance with the media in his machine especially in the warmer summer months. When the mercury was rising so was the centre of Nick’s PPF media as it became more malleable and softer in the warmer summer temperatures.

The bowing effect that the temperature was having on the media would cause the blade to either snag causing the media to wrinkle or drag across the surface leading to unnecessary, unwanted and costly wastage.

However, there was a simple fix. Shackleton’s FC8000 was equipped with only two push rollers which were positioned at either end of the media, but in order to stop the media buckling in the middle, Graphtec were able to fit an Additional Push Roller Assembly. Adding this extra roller keeps the media flat and held firmly at all times, eliminating the troublesome buckle.

The ability to add an extra Push Roller is a stand out feature of the FC series range, unfortunately this isn’t possible with a CE Series Machine. With Shackleton’s FC8000 back up and running with the new Push Roller Assembly in place it was back to business as usual.

Shackleton talked Graphtec through the process on a brand new frame that had come in for wrapping prior to being built up. This wasn’t a frame that Shackleton had worked on before so he had to draw up the template while he worked on the frame.

Firstly, the frame is fully degreased (a much simpler process on a frame that hasn’t yet seen any outdoor action) which makes sure that the adhesive sticks perfectly without any bubbles forming. Once the template is cut Shackleton wets the frame and film to enable it to slide into position with ease, similar to the process used when applying window tint material to glass.

Once fully wrapped, the frame has to dry out before it can be either built or ridden. The wrapping process takes between 3–5 hours depending on if Shackleton has the template already drawn up or not.

Submit your news and video content to journo@practicalpublishing.co.za

Subscribe to our YouTube channel, read the top 5 stories weekly on WhatsApp or sign up to our newsletter.

GRAPHTEC https://www.graphtecgb.co.uk