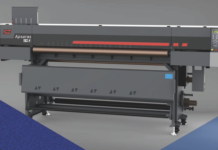

Prestige Print & Sign in the Netherlands recently purchased an Anapurna RTR3200i LED from Agfa.

‘We seek out customisation jobs as much as possible to stay away from the bottom prices you encounter in our market. Our strength is our own studio with creative and innovative employees,’ said Einbert van Rees, director of Prestige Print & Sign. ‘We always link creativity to implementation in an efficient manner.’ The recently purchased machine from Agfa also fits into that picture.

‘My sons manage production, I am more of a designer and am involved in innovation and creation,’ he said. In addition to his work as a graphic designer, Van Rees started painting billboards in the evenings 35 years ago. From this activity, his company Prestige developed over more than three decades into a national player in the field of XXL prints, product presentations and indoor and outdoor signage. When the print runs grew, screen printing was first introduced and is still considered an excellent method for one or two colours, followed later by digital printing.

‘We take on all kinds of jobs, but we have specialised in printing on boards,’ said Van Rees, who, in addition to an eco-solvent printer from Epson, has a 2m wide hybrid machine from Durst and a flatbed printer from Fujifilm.

‘We are situated among carpet manufacturers, for whom we make many displays from rigid substrates.’ To communicate clearly to the outside world, Prestige has divided its activities into five categories: retail, car signs, studio, outdoor & indoor signage and Plaatprinten.nl (board printing). The latter is an online ordering platform that can serve both companies and private individuals. ‘Think of photo panels, but also wall decorations, whether or not combined with acoustic solutions. For example, our Wall Parade, an acoustic slat wall available in both wood structure and printed with an image, is really trending at the moment.’

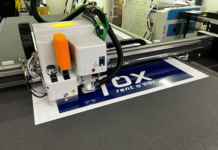

To be able to produce Airtex seamless (photo) wallpaper in-house, the company looked for a new roll-to-roll printer. The specific request from an industrial customer to print on a polyester fleece material put this search in a completely different light. ‘We make a semi-finished product. Due to the further processing process, dye sublimation is not an option. Sublimation ink then dissolves, it turned out, whereas UV ink does not. But because the ink bleeds through when printing the fleece, you do need a machine with an ink collector. We looked at various printers, but ultimately opted for the Anapurna RTR3200i LED from Agfa. We chose CMYK plus the white option.’

The six print heads address ink droplets of 12 picolitres, allowing users to print easily readable letters of 4 dots, according to Van Rees. ‘We install two duo rolls next to each other for the fleece material, but we can now also print Airtex across the full width on this 3.2m wide printer.’

Because the fleece is a semi-finished product in large volumes, speed is important, but so is a professional winding system, Van Rees indicated. ‘We do two hundred linear metres of printing work in one go; then you must be sure that the material is placed tightly and straight on the roll. This Anapurna can print a maximum of 127 square metres per hour, but if we print white, we print approximately 40 square metres per hour.’

Because the printer is equipped with LED UV lamps, more critical materials can also be printed. Van Rees said, ‘We always look for custom solutions and love specials. For example, we have now printed sun blinds on this machine for a partner, for which durability tests have now been carried out.’

THUNDERBOLT SOLUTIONS

+27 11 657 7000

www.thunderbolt.co.za