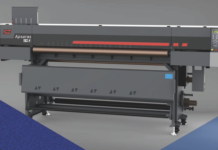

The new Oberon RTR3300 – a dedicated 3.3m high-end roll-to-roll machine – comes in a four colour plus white, and a six colour version, depending on user needs and preferences. In ‘express mode’, the Oberon RTR3300 hits an impressive 150sqm/h, while still delivering Agfa’s well-known exceptional image quality.

In ‘production mode’, the Oberon reaches a consistent 85sqm per hour. The dual-roll option is capable of handling two rolls each up to 1.6m wide, doubling the total output. The UV LED inks on the Oberon RTR3300 were optimised for flexible media and excel in the smooth printing of solid colours. They obtained the highest category of Greenguard Gold certification, which means they meet some of the world’s most rigorous chemical emissions standards and can be used in sensitive indoor environments like schools or healthcare facilities.

The UV LED inks on the Oberon RTR3300 were optimised for flexible media and excel in the smooth printing of solid colours. They obtained the highest category of Greenguard Gold certification, which means they meet some of the world’s most rigorous chemical emissions standards and can be used in sensitive indoor environments like schools or healthcare facilities.

Wide media scope

The Oberon RTR3300 covers significant media diversity and a wide range of applications, enabling print service providers to execute all their customers’ creative wishes, while also inspiring them to explore new directions.

In addition to its air-cooled LED curing lamps, the Oberon RTR3300 features a unique water-cooled table that keeps the printing zone at room temperature. Therefore, print service providers can smoothly process any kind of heat-sensitive roll material, including lower cost media. The dedicated mesh printing functionality makes printing on mesh (with or without liner) more convenient than ever.

User-friendly, efficient and reliable

The printer was designed with a view to offering convenience, lean operations and peace of mind. Thanks to a unique media loading setup, a single operator can quickly load the media. The smart multi-queue functionality guarantees effortless job planning in view of the available materials. The free fall option, which may be used to print on demand, reduces media waste. A light box next to the printing area allows for on-the-spot quality inspection of backlit prints, while a double light curtain ensures that jobs don’t get interrupted and media wasted, even when an operator accidentally moves into the safety zone.

Taking printing to the extreme

‘When developing the Oberon, we once again focused on merging extreme productivity with extreme quality, in addition to delivering the lowest ink consumption levels and reduced overall operational costs. It is a position to give print service providers a competitive edge,’ said Tom Vermeulen, Head of Sign and Display, Agfa.

‘This new engine builds on decades of experience in developing and manufacturing versatile large format printing solutions. Our unique systems approach integrates and optimises engine, ink, media, workflow and colour management to ensure the highest quality, consistency and reliability.’

Submit your news and video content to journo@practicalpublishing.co.za

Subscribe to our YouTube channel, read the top 5 stories weekly on WhatsApp or sign up to our newsletter.

|

LOCAL DISTRIBUTOR |