ZSK and UNWIND3D have collaborated to redefine the standards of thermoplastic as well as thermoplastic composite manufacturing – turning advanced ideas into products and scalable, high-performance solutions. This collaboration empowers companies to: innovate faster, build know-how effectively, and have a bespoke guiding and learning experience.

By combining ZSK’s Tailored Fibre Placement (TFP) technology with UNWIND3D’s automation and composite manufacturing expertise and a worldwide network of partners, customers gain a complete, efficient and scalable path from concept to industrialisation.

Located in Arsago Seprio, Italy, UNWIND3D’s open-space facility merges office, meeting, and production areas, providing an inspiring environment where engineering, testing, and production come together.

Customers coming from all over the world can experience the entire workflow: from fibre selection to a fully consolidated part, all within one integrated environment. UNWIND3D ensures shorter product development times and maximum process control, while providing a personalised experience.

U3D equipment:

Beside being a showroom for ZSK TFP machines, where customised lay-up preforms up to 110cm x 65cm can be manufactured, Unwind3D offers:

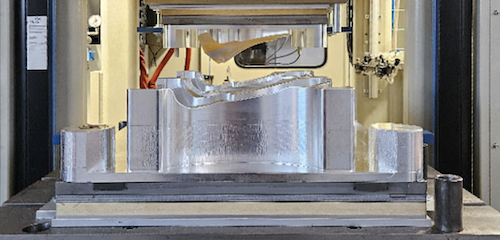

– 1 x U3D proprietary advanced development cell: high automation, induction heating, and in-house software for precise temperature and pressure control, designed for thermoplastics as well as composites parts up to 1m x 1m.

– 1 x U3D proprietary production cell: high automation and in-house software for precise temperature and pressure control, designed for thermoplastics as well as composites parts up 0.8m x 0.8m

– 2 x customised R&D presses: 70 tonnes each, modified for fast heating and cooling with 70 × 70cm plates.

ZSK STICKMASCHINEN

https://www.zsk.de/en/