PLASTGrommet will showcase the latest additions to its large format finishing automation range, including the North American debut of three of its newest technologies.

The company will showcase these solutions at PRINTING United Expo 2025 in Orlando from October 22-24.

The three new PLASTGrommet solutions making their North America debut on the PLASTGrommet booth include:

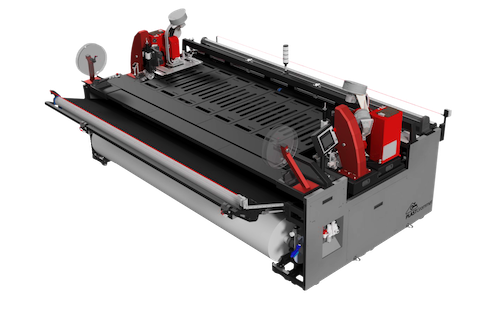

All In One Edge: Offering the same integrated welding, grommeting, and cutting capabilities as PLASTGrommet’s flagship All In One banner finishing machine, the new entry-level All In One Edge opens up the possibilities of finishing automation to mid-volume large-format printers.

Hybrid TexWiz: Built on the All In One platform, PLASTGrommet’s new Hybrid TexWiz integrates a sewing module to enable automated sewing of hems along with grommeting and cutting of airmesh fabric banners. This enables hybrid finishing automation for print shops simultaneously producing PVC and textile-based banner products.

FlexiPress hand press: Building on the popular HPS025 model for grommeting PVC banners, the brand new FlexiPress will launch at PRINTING United Expo and enables businesses to use both brass and clear grommets on a single hand press.

In addition to these newly launched solutions, PLASTGrommet’s demonstrations at the event will include:

Easier media handling: using the Evolve Air Welder multi-purpose hot air welder, PLASTGrommet will debut a new conveyor belt that works in synchronisation with the Evolve’s traction rollers to allow for easier material handling with longer welds.

Automated finishing of fully recyclable textile banners: using the TexWiz sewing module, PLASTGrommet will demonstrate the environmental benefits of textile banners throughout the event. For example, when paired with PLASTGrommet’s proprietary clear grommets, polyester banner materials can be recycled with the grommets still intact, removing the need for separation during the recycling process.

Alongside the recently launched technologies, PLASTGrommet will showcase a range of products designed to streamline and automate large format print finishing, from grommeting equipment and its proprietary clear plastic and metal grommets, as well as media roll lifters and smart storage racks for optimal organisation.

Rafa Menéndez, Head of Sales and Marketing at PLASTGrommet said, ‘As print technologies accelerate, large format finishing can often become the bottleneck that holds businesses back. At PLASTGrommet we want to change that, which is why our solutions are designed to streamline every step of the finishing process through automation, helping printers of all sizes stay productive, profitable and competitive.

‘With innovations such as our new Hybrid TexWiz, we’re also helping them to future proof their businesses by adapting to changing demands in the large-format print market.’

Other solutions being showcased:

– The Finishing Station, with a reduced footprint, offers users a machine that welds and sets grommets in a single step. It has been upgraded with a camera to read grommet marks, streamlining use for operators.

– Queen and Speed Queen Semi-Automatic Presses for applying grommets.

– Evolution, Autocross, and Multipress Automatic Presses suitable for a variety of materials.

– Proprietary clear plastic and metal grommets, manufactured in-house in Spain by PLASTGrommet.

– RollMAX E-Lifter for large diameter heavy rolls up to 450kg.

– Compact E-Lifter PRO, a hydraulic media lifter for rolls up to 300kg.

– Compact Lifter, a manual media lifter for rolls up to 200kg.

|

LOCAL DISTRIBUTOR |