Blackstone Tek, a leading manufacturer of carbon fibre wheels, has reported an exponential increase in productivity following the installation of a Zünd G3 L2500 Digital Flatbed Cutter, purchased from Midcomp. The G3 is fast, compact, and complies with the highest safety standards. This solution is a true Swiss quality product and is uncompromising in precision and design.

Blackstone Tek brings customers the most technologically advanced wheel on the planet. The company specialises in the same manufacturing processes used by Formula 1 and NASA. At their production facility, their technical team combines highly specialised material science and aeronautical engineering with cutting-edge process manufacturing and automation.

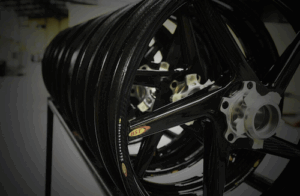

The company’s current portfolio consists primarily of safety critical carbon fibre composite parts, such as high end motorcycle or high performance car wheels, as well as some aesthetic and aerodynamic components, like front diffusers, exhaust caps or air intakes for certain high performance vehicles.

The majority of the carbon composite components they manufacture for the automotive industry are constructed using plies, which are small strips or different shapes and geometries of carbon fibre sheets. Most of the company’s components consist of well over 200 of those unique plies.

The carbon fibre that is purchased and used in all of Blackstone Tek’s products comes in a roll that is typically about 1.2m wide, roughly 60m in length, and has a thickness that is typically 0.3mm.

It is rolled out over the bed of the Zünd cutter. The machine then cuts the carbon sheet into smaller shapes, which then get stacked up and built inside of a mould to create the carbon fibre wheels that Blackstone Tek manufacture.

‘Compared to any other flatbed cutter on the market, the Zünd offers fast, precise and accurate 24/7 cutting and production, in a market where things can change on a daily basis. The graphite like structure of carbon fibres enables them to conduct electricity, and this property is retained even in dust form. Consequently, the Zünd G3 at BST incorporates a unique feature where all electrical components are safeguarded with carbon fibre protection. The modules are sealed, all circuit boards are coated with a special coating, and a negative pressure is maintained in the power cabinet to repel dust,’ said Darryl Braithwaite, Sales Executive at Midcomp.

‘The Zünd has an IJT tool to print and mark the pieces that Blackstone Tek have cut, so when it comes to manufacturing, they can use the correct pieces in the correct order. This tool is also prevalent in the aeronautical industry and allows seamless production once cut pieces need to be put together.’

Incredible Speed And Efficiency

Blackstone Tek’s mechanical design engineer, Michael Lockey, explained the noticeable differences between the Zünd G3 and an older CNC cutter they previously used: ‘We’ve seen about a 75% improvement on cutting efficiency as well as time saved on the Zünd compared to the old machine.’

‘The old machine couldn’t do actual ink printing, such as fine numbers or any sort of writing that we need on our cut outs. As for the plies that we use for our manufacturing process, there’s a very specific order in which those plies need to go into the mould. Each shape gets a specific number, and it runs sequentially. The Zünd allows us to label and print on the ply when it’s being cut, saving us so much time.’

The Zünd also gives the company greater control over the geometry, or the general shape of the cut out, of the plies, as well as higher accuracy compared to the older cutting machine, ‘Our old cutting machine was quite limited in terms of its functionality and the complexity of the shape that we could get from it.’

Additionally, the Zünd’s longer service life was cited as a benefit. ‘We also got far more breakdowns on the older machine compared to the Zünd,’ added Lockey.

Targeting New Sectors

Lockey added that around 200 plies are needed for a motorcycle wheel, and 400-500 plies are need for bigger motorcar wheels, which require a larger volume of carbon fibre. Now that the company can process this larger volume with the Zünd cutter, they can start targeting the motorcar wheel sector.

Keeping Up With Market Changes

‘People want new, fresh and exciting designs that push the envelope of what’s thought to be possible in the carbon fibre space. The Zünd cutter helps us keep up with these market changes by allowing us to develop, cut and produce new concepts at a far faster rate than we were ever able to do before,’ said Lockey.

The primary benefit of the G3, added Lockey, is the ability to keep up with the demand for, and the market changes in, customisation, as well as optimisation of their current product line. ‘If there’s any optimisation that the engineers can foresee in the product that we have historically made, it makes it far easier for us to make those changes to keep up with the constant demand of a lighter, faster and higher performing product.’

Excellent Customer Service And Support From Midcomp

‘Whenever we have a callout or require a service or a change of any components, Midcomp is always on time. They’re always super friendly and helpful in explaining to us why certain things occur. They’re very fast to troubleshoot and provide the solutions that we require anytime we need assistance with a problem.

‘The Zünd is a critical part of our production process – to be without the cutter for even two days is a massive knock to our productivity. So the main requirement for us was post-purchase support: being able to call Midcomp, have them fix any potential problems and for us to be back up and running within a day.’

‘Midcomp has been dealing with Blackstone Tek since 2018 and will continue to do so for many years to come’, added Braithwaite.

Blackstone Tek’s Unique Offerings

Lockey said that they are the best at what they do: ‘Safety critical components is quite a niche industry when it comes to carbon composite parts. We not only manufacture these carbon composite parts – with the highest attention to detail to ensure that they’re not only lightweight, high performing and capable of the loads required by the vehicles that they go onto – but we also pay very strict attention to our quality control process.’

‘This ensures that the end product is absolutely perfect, and that once the customer receives their Blackstone Tek product, they’re 100% happy with that purchase.’

|

LOCAL DISTRIBUTOR |