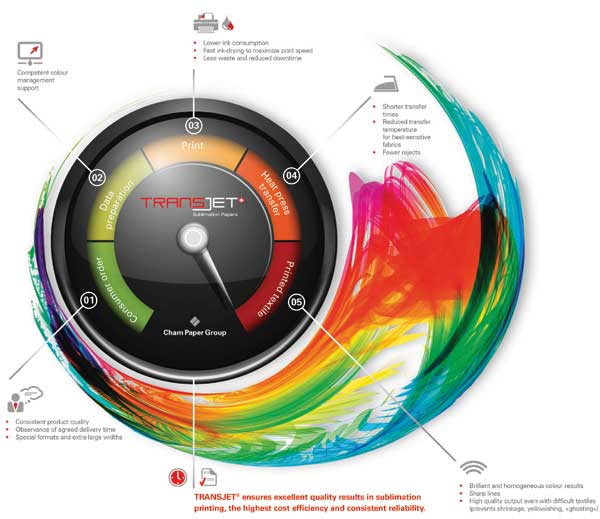

TRANSJET® Swiss Sublimation Paper Sign Africa Journal Mar/April 2017 | Click here to view online

TRANSJET® ensures excellent quality results in sublimation printing; the highest cost efficiency and consistent reliability. To enable customers to make optimal use of the potential of the latest generations of printers and inks, the company is always working to improve and further develop its sublimation papers.

TRANSJET® Boost, the ink is instantly absorbed by the highly porous coating surface and passed through capillary tubes into the coating. During the transfer process, the capillary tubes act as a turbo channel, speeding up the colour transfer by boosting the colorants out of the coating. Applications include: transfer onto various polyester materials, such as: sportswear, banner, flags, skis and snowboards. The paper is available in 85GSM and 130GSM.

The ultra-light grammage of this coated sublimation paper guarantees extreme cost efficiency in high volume productions as they are usual e.g. in the garment manufacturing industry. TRANSJET® Boost, instant-dry (350sqm/h) is for use in industrial high-speed printers and features:

- Ultra-fast ink absorption and drying.

- High ink loads possible.

- Brilliant colours and enhanced colour release and densities.

- Extra large gamut.

- Excellent transfer rates.

- Excellent runnability and outstanding efficiency

- Excellent colour brilliance. The special coatings hold the ink on the paper’s surface. This increases the transfer rate and ensures brilliant homogeneous colours.

- Consistent quality characteristics. The performance and dependability of TRANSJET® with regard to colour transfer and runnability ensures added reliability to all of the print service provider’s processes.

- Precise transfer results. TRANSJET® offers a solution which completely prevents 'ghosting', a kind of shadowing, because the sublimation paper bonds with the textile during transfer. This guarantees homogeneous colour transitions and high line sharpness on the textile.

- Shorter production times. TRANSJET® is designed for the latest generation of printers. The good drying properties of this sublimation paper allow faster print production and shorter transfer times. This reduces costs and saves time.

- Lower ink consumption. As TRANSJET® holds the ink on the surface, ink consumption can be minimised without any need to sacrifice colour brilliance.

- Ideal for extra-wide formats. Due to the papers’ high stability, your extra-wide production of up to 3.20 m runs reliably and efficiently.

- Reliable production. As the ink penetrates the coating in a controlled manner, corrugation (wet cockling) is minimised during printing. This reduces both downtime and repair costs.

- Fewer rejects. Due to the activated tack effect of TRANSJET® Sportsline triggered by the heat in the calender, there is now hardly any shrinkage of textiles during processing.

- Secure margins. Quality fluctuations or reprints due to non-compliance with stipulated print qualities, along with high additional costs which reduce margins are avoided.

| This is a Signage Industry Advertisement sent on behalf of an advertiser. | ||

|

||